The Race to Alaska (R2AK) is an un-supported challenge in which reliable communication and navigation is important, but energy supplies are often limited. Many of the smaller boats want to be light to make sailing or human propulsion faster, so taking tons of batteries isn’t an option. Solar charging systems can be limited by inclement weather. And getting wet is pretty much guaranteed on a small (<20′) boat.

Electrical system for cruising 21′ cat and Team Puffin (R2AK 2015, ~9.0 kg):

Here’s the system that Team Puffin used in the 2015 R2AK. This set-up was derived from systems that were used aboard the same Wharram Tiki 21 sailboat (“Milagra”) during summertime cruises over the last 5 years.

- Pelican case (45 cm long x 35 cm deep x 18 cm thick; with wooden dividers/brackets glued in using Shoe Goo)

- Motorcycle battery, lead-acid (3.3kg [7.3 lbs])

- 10 Watt PowerUp solar photovoltaic panel

- Battery Tender Solar Jr charge controller

- Marine (stainless steel) wire terminal

- 16 gauge marine wire

- Dual cigarette lighter jacks (with covers to keep out spray/salt/etc)

Here’s some pictures of it in action during the cruising era:

Typical cruising loads as well as the loads required by Team Puffin were served through USB chargers that fit the cigarette lighter jacks. The main power demands were for:

- iPhones (with Navionics, MarineTraffic, and other apps)

- VHF radio (plus a back-up)

- iPad (only aboard with Team Puffin, and not used much as iPhones sufficed)

Electrical system for Team Take Me to the Volcano (R2AK 2016; ~7.8 kg)

The Tiki 21’s electrical box is being modified for use by Team Take Me to the Volcano in this year’s (2016) Race. Matt’s main charging needs are:

- VHF (plus a back-up)

- Phone

- Lithium-ion battery pack (a 20,000 mAH one costs ~25$ now! that’s 20 AH, so seems cost effective compared to larger motorcycle-sized lithiums…)

Most other items will be powered by disposable (mostly lithium AA) batteries:

- GPS

- Flash light / anchor light

- Head lamp

- Running lights

- R2AK SPOT (lithium only)

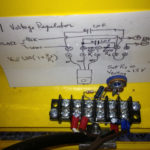

Based on these comparisons, here are the main modifications and improvements we are making:

- Lighten up the whole system by switching from lead-acid to a lithium battery, and possibly by using a less rugged waterproof case (new Pelican Air 1485 of sufficient outer dimensions is 2.1 kg, saving about 800 grams over current case)

- Add energy storage by using “bricks” now mass produced for recharging phones/etc that are charged via the USB ports

- Solder, stabilize, and marine-ize all wiring, terminals, and components

Here’s the final result. This may still be too heavy for Matt to use in the R2AK, but it is an incremental improvement in the cruising system I’ll use aboard the Hitia 17 or Tiki 21.

The main changes were:

- Lowered total mass by about 2.0 kg overall.

- The big savings of 2.1 kg was from switching from Pb-acid to lithium iron phosphate battery. We take a little hit in capacity (going down from 12 to 9 Ahr), but presumably that can be supplemented by adding a USB lithium battery brick.

- Considered a Pelican Air, but the mass savings for the smallest that would fit the 10W panel was only 500 g.

- The Bioenno charge controller added ~110 grams over the BatteryTender one (but I hope it handles load vs battery maintenance more intelligently…

- I re-sealed the holes in the case with Tap Plastic’s recommended 2-part glue for polyethene (adding some glue mass, but simplifying the seal of a big historic hole in a way that reduced mass a bit).

- Testing extra capacity with Matt’s Aukey 20 Ahr brick, but may end up using a smaller one that I own…

- All wires are now terminated, soldered, and heat shrink tubed. Battery, controller, etc are also much more secure — either lashed, screwed, or velcro-ed down. I was surprised to see how much electronic complexity is inside the charging base for the VHF. In a feeble effort to protect it, I added some shoe-goo to the perimeter of the base cover which is otherwise just held on by a single central (tiny) screw. An added benefit of glue-screwing the base to the wooden board (which I moved and glued to the handle/edge) is that now the VHF can be used (for listening to weather, or even transmitting while plugged into the charger…

LiFePO4 battery details

I ran into two tricky bits in implementing the lithium battery upgrade.

First, not all lithium iron phosphate batteries are the same. Some are aimed at maximizing lithium cranking amps (LCA) while others can tolerate deep cycling. While batterytender.com offered an attractive lithium option (12V, 120 LCA, 0.5 kg, $100), they emailed to say that it really wasn’t appropriate for deep cycle use in a marine setting. After searching around (and finding this very interesting Canadian electrical engineer who is making a solar charge controller for lithium PO4 battery banks), I ended up at BioEnno Power looking at their 12V series of LiFePO4 batteries about which they say:

These are Deep-Cycle Batteries for extended continuous use, not to be confused with High-Rate Batteries which are for starter applications only and not for extended continuous use.

I ended up choosing the BioEnno Power 12V, 9Ah Pb-acid equivalent LiFePO4 deep cycle battery.

Though it is only ~1/2 the mass of the current Pb-acid battery in our system and still costs ~4x as much, I’m excited for the weight savings and to try this new technology. I was also motivated to go with them since they sell an AC charger ($22) and a 12V/10A solar controller ($40) that specify having a charging algorithm that is appropriate for LiFeSO4 batteries, though it’s not clear to me whether or not they use a 5-stage LiFePO4 charging algorithm that Battery Tender recommends.

Second, the weight savings seemed to vary a lot depending on the LiFePO4 battery manufacturer, or possibly the intended application: deep cycling vs high-rate. For example the Battery Tender 12V/120LCA battery (which they bill as equivalent to a 7-9Ah Pb-acid battery) weighs 0.5 kg which is is ~1/7 the mass of the current Pb-acid battery’s 3.3 kg. In contrast, the BioEnno 12V/9Ah battery has a mass of 1.18 kg — about 1/3 of the Pb-acid mass. Even the 240LCA () Battery Tender option weighs only 0.8 kg (1/6th Pb-acid mass). What could account for this factor of ~2 difference in LiFePO4 battery mass? (Bolted vs welded connections between cells?)